Reducing pipeline corrosion with cathodic protection

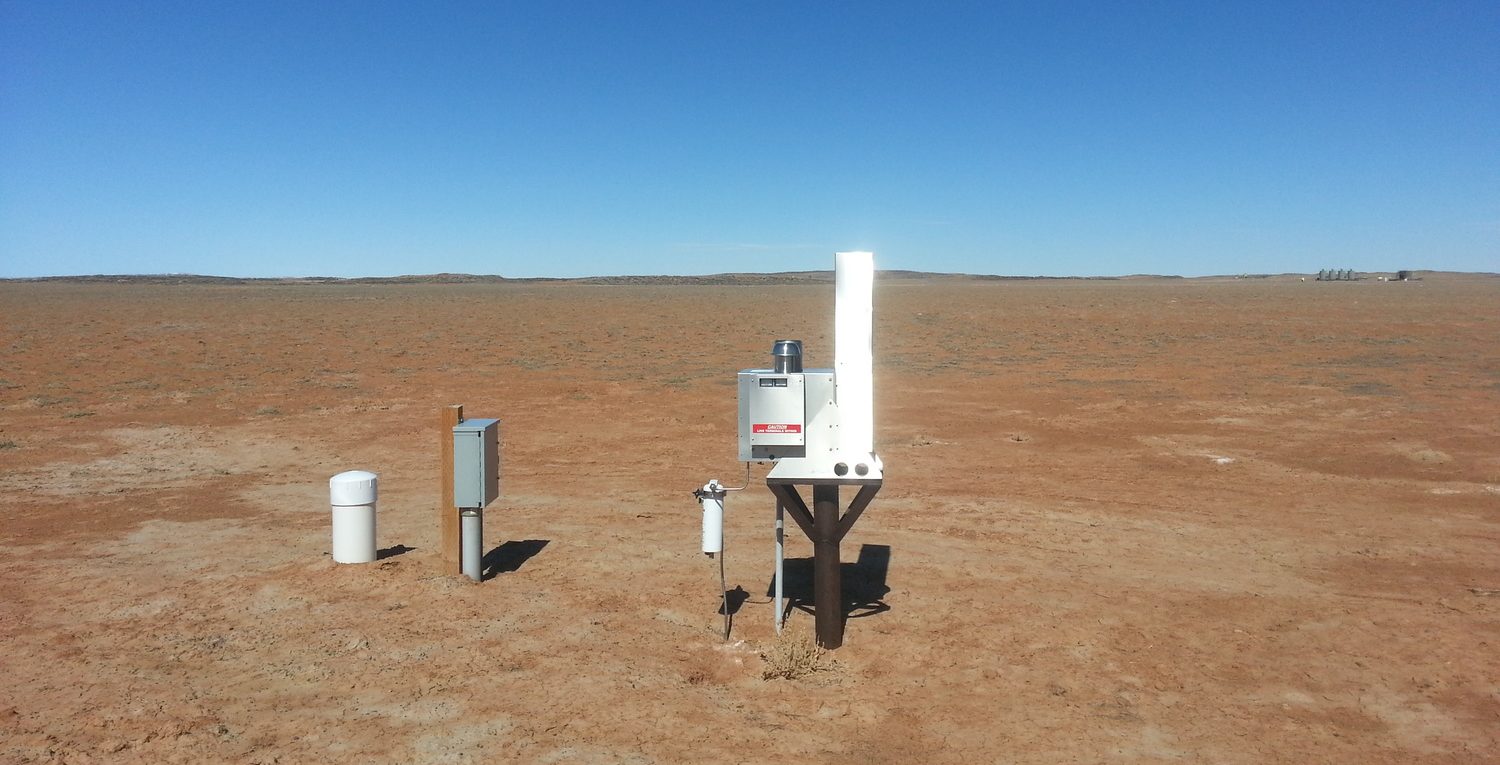

Cathodic protection – a process where electric current is supplied to a pipeline – is an efficient method of preventing corrosion. However, for remote Australian pipelines, finding a continuous power source to provide this current can be difficult. Thermoelectric generators (TEGs) are proving to be the best power source for cathodic protection because they are low maintenance, have high reliability, and don’t require large battery banks.

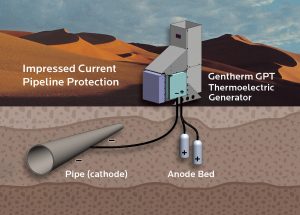

Corrosion occurs due to an electrochemical reaction between two electrodes: anodes and cathodes. Cathodic protection is an effective way to combat costly corrosion problems because it minimises the differences between these two electrodes. Pipelines are normally anodic but when the electric current is supplied the pipeline will become cathodic.

To ensure a cathodic protection system is economically feasible for a project, it must have a cost-effective method of supplying the electric current. This is where TEGs have proven to be successful.

Alternative to AC rectifiers

Alternative to AC rectifiers

Dominic Pituch P.Eng. Sales Engineering Manager at Gentherm Global Power Technologies (GPT) – one of the few manufacturers of thermoelectric generators (TEGs) worldwide – said the benefits of TEGs lie in the functionality of their cathodic protection system panels, and their ability to supply continuous power unattended.

There are now more than 45,000 TEGs operating globally. TEGs provide an alternative solution to a rectifier which requires AC Power, and because the cathodic protection panel supplies DC power, it allows operators to easily connect directly to the anode bed.

“A TEG is a DC generator that impresses current directly into the structure without the use of an AC rectifier,” Mr. Pituch said.

“GPT thermoelectric generators are used when AC grid power is unavailable or simply too costly. Because thermoelectric conversion is a solid-state phenomenon, TEGs have no moving parts and operate reliably for long periods of time without maintenance or supervision.”

Cost-conscious power solutions

Cost-conscious power solutions

Companies using cathodic protection are generally cost-conscious, as they want to reduce the effects of corrosion on their pipelines in the most economical way possible.

Mr. Pituch stated that TEGs are perfect for gas pipeline cathodic protection applications in remote regions of Australia because they have very low operating and maintenance costs, and can run without any supervision.

“Today’s users of cathodic protection are highly cost conscious, and most expenditures are based upon sound economic analysis to justify capital and operational costs,” Mr Pituch said.

“GPT TEGs are a proven reliable source of continuous current, and should always be considered for cathodic protection applications.”

GPT TEGs are made of stainless steel, weatherproof materials which mean sheltering is not required, therefore saving on construction costs. TEGs also don’t require much fuel to run, for example, a 100W Model 5100 generator can impress 10 amps continuously into a 1 ohm ground bed, at 10 volts, and consume just 5000 liters of LPG or 3400 m3 of natural gas per year.

TEGs work by converting combustion heat directly into electricity and only need preventative maintenance once a year to last their 20-year design life. For example, a Model CP5120L unit in Canada that was manufactured in 1987 has been providing cathodic protection for a pipeline for 30 years and counting. The unit first required service in 1996 when its power unit was changed. It returned in 2017 and is now back out in the field.

Minimising corrosion in Australian pipelines

Minimising corrosion in Australian pipelines

GPT has more than 40 years of experience supplying DC power in cathodic protection applications around the world, and is now supplying TEGs in Australian pipeline projects.

Wade Elofson, the founder of Powered, an Australian energy and resource-focused business development company, said given the industry’s current economic climate, it’s important for companies like GPT to continue providing innovative cost-effective ways to reduce maintenance and operating costs.

“Corrosion can be a huge problem for gas pipelines in Australia, with repair and replacement costs adding a significant amount to the budget,” Mr Elofson said.

“Cathodic protection has been an effective solution for a while now, but having a reliable power source, especially in remote regions of Australia, is a very important consideration for any cathodic protection pipeline application.”